Will Expand Calibration Range – Interviews

Will Extend the Calibration Range

Enelsan's TÜRKAK-approved and 100% domestic production calibration stand has been getting ready so that it can measure different diameters. When the R&D work to be carried out is completed, equipment of larger and smaller diameters will also be calibrated at the calibration stand. The aim of the brand is to make the stand more beneficial to the country's industry by expanding the scale of the diameters that can be measured in this way.

Enelsan Sales Engineer Doğan Ceylan, with whom we had an interview about the brand's energy sector applications, added the following on the subject; “We are trying to make our calibration stand more useful for the Turkish Industry by making the diameters a little larger and smaller.

In addition to this, we are working on a flow meter that is not produced in Turkey, which measures with a different principle. Therefore, the new flowmeter I mentioned, increasing the range of flowmeter measurements that the calibration stand can calibrate, and the tightness test device are our R&D studies that we are currently active in. “

What are your firsts in the industry?

Enelsan is the company that produces the first electromagnetic flowmeter in Turkey. We produce completely in Turkey and we have a domestic product certificate. All of this product is made in our production facility and in-house. An electromagnetic flowmeter is a flowmeter that measures a device with conductivity. This equipment, which has analog and digital outputs, can be easily adapted to any control and monitoring system. Ertan Söylemez founded the company in 1976 and a partnership was made with a different German company for many years. Until 2012, a solution partnership has been carried out in this way. With the experience and knowledge gained from here, we started to produce our own product. In addition, our pressure transmitters are our own production. Our temperature transmitters are also among our products. In addition, we can manufacture motion sensors and devices that measure open channel – spillway.

How do you measure open channel?

In the open channel; You narrow the channel with a weir and you can easily see the flow information by transferring the information to the electronic panel, which we call OFC 2000, with an ultrasonic level measurement device that works with the help of sound on the water collected in the middle of the channel. We also have a weir project for an open channel with a width greater than 70 inches.

How much precision can we talk about in such a measurement?

Although not as much as an electromagnetic flowmeter, if the weir calculation is done correctly, we can achieve a sensitivity of maybe 2 percent.

What are the advantages of being a local manufacturer for you and the brands you serve?

Being a Turkish brand has both advantages and disadvantages. There is a certain opinion in Turkey, it is undeniable. Frankly, there is not much trust in the producers in Turkey. There are mostly German origin brands in the sector. If a facility cares too much about measurement, they generally prefer products of German origin. They find these products more reliable. They are superior to us in terms of price, but there are many facilities in our country that cannot even afford to try the products in Turkey in terms of reliability. Apart from that, we are proud to be a domestic product.

In fact, references and perhaps free use of your product may be needed to understand whether your product is of good quality or not?

Of course, we have such sales examples such as that a facility contacted us and asked for a solution after the products of a European brand that it had used before, made mistakes very often. We gave our products for free for a while and allowed them to try our products. The facility, which did not experience any problems afterwards, decided to supply our products. In fact, this company was a big generator company whose name you heard very often.

Your lead times and being a brand capable of product development are also your advantages?

Of course, we have a additionally calibration station. This station is also TÜRKAK accredited. Only we own this station in the private sector. As a state subsidiary, only TÜBİTAK has this system. We have already carried out the installation of this system used there.

Our R&D studies also continue. Currently, we can issue accreditation certificates up to medium diameters. We can provide our own company report for very large diameters. We are currently working on expanding these diameter ranges. We are working in partnership with TÜBİTAK on this issue as well. This year, we aim to further develop these ranges. Because one of our biggest advantages is that we have domestic production.

In this way, we realized a special production for a large company in Zonguldak Ereğli. The products of some brands in the market become standard and you can make any changes to these products. However, if the area to be flanged is incompatible with the body of the flowmeter, you can keep the body longer than the line and extend the area to be attached to the flange. So you can easily change the production. Our friends working in the technical service department have at least 10 years of experience in the sector so far. They commissioned, repaired and programmed not only Enelsan devices but also products of many brands. We have a serious knowledge of service. So far, I have never seen them fail or hesitate in any work. Our device comes out of production with everything completed. I can say that our calibration station gives us a great advantage when a zero production will be made. Because in Turkey, there are generally companies that want flowmeters to have an accredited calibration certificate. We can document and present this directly. At the same time, we can accredit different devices and present their documents.

Do you support the need for spare parts or the modernization of the existing product?

We provide services in devices that are not included in our portfolio. In addition, Enelsan Bopp & Official distributor of Reuther Messtechnik GmbH in Turkey. Bopp & Reuther is the world's number one positive displacement counter and the inventor of oval wheel counters. As Enelsan, we can only buy and sell the products of this brand in Turkey. When a different brand is requested, we also do provide service for measurement groups other than ours. Furthermore, If desired, we can carry out similar guidance studies on many issues regarding price information and measurement. Recently, a leading company in its sector in IMES called and asked us for help to fix the incorrect measurement problem of existing non-Enelsan flowmeters. We did provide a solution to this customer with a couple of hours of effort and work.

How are your R&D studies created? What are the inspirations when setting goals in this regard?

Currently, with our leak tester, we are able to check points with gas flow, such as ovens and stoves, where leakage is generally not desired. This device is quite affordable, compared to its counterparts, in terms of cost to our customers. This device is an analog device, but the price-performance balance is extremely successful. We are conducting R&D studies in order to make the leak tester even more technological and ergonomic.

Currently, our priority is to expand the calibration range of 100% domestic production and calibration stand. Calibration is an extremely important issue for any device. We are trying to make our calibration stand more useful for the Turkish Industry by enlarging and reducing the diameters a little bit. In addition to this, we are working on a flow meter that is not produced in Turkey, which measures with a different principle. Therefore, the new flowmeter I mentioned, increasing the range of flowmeter measurements that the calibration stand can calibrate, and the tightness test device are our R&D studies that we are currently active in.

Mr. Doğan, how did you complete 2015 as a brand?

Since I personally deal with the sales figures in the department, I can summarize it as follows; There is a huge growth in 2015, compared to other years. Our business goes with hot sales as well as the state tenders we participate in. Because we can keep the prices at considerable level, hereby we have a very high chance of getting these projects. We did very well with the state in 2015. Their returns for us have also been quite satisfiying.

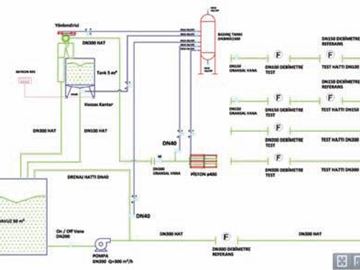

A significant part of the revenue generated by the company was reserved for the systems we call the skid system. The skid system allows you to measure the petrochemical derivative products coming to the port for storage, thanks to the piping and metering system on it. We started skid production last year. So far, we have carried out this work for 4 companies. Some of these companies are in the North East Black Sea Region, and a few are in the ports here. In addition to all these, we also sell complete systems. We also carry out projects that we provide control, automation, scada, level monitoring and product supply with several companies.