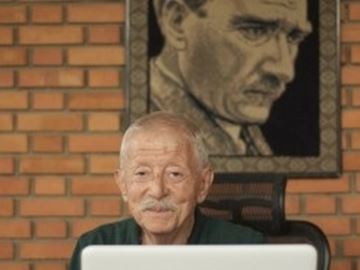

Innovation and Hi-tech production in Turkey Interview

Innovation and Hi-tech production in Turkey

Ertan Söylemez always emphasizes the necessity of further innovation studies and high-tech production in order to reach this target that Turkey has an export target of 500 billion dollars in 2023.

Enelsan, which manufactures electromagnetic flowmeters with Türkak Accreditation certificate, currently mainly serves water and wastewater processes. We talked to Enelsan Board of Directors, Ertan Söylemez, who described the brand as Turkey's first and only domestic flowmeter manufacturer, about the company's product features and the difficulties of being a domestic manufacturer in Turkey.

“HI-TECH PRODUCTION MUST BE MADE IN TURKEY”

Turkey aims to export 500 billion dollars in 2023. For this, we need to be able to produce value-added products. Turkey imports 250 billion dollars in 2013 and exports 140 billion dollars in return. There is a deficit of 100 million dollars, and in the imports made, only the manufacturing products made by assembly. More innovation and Hi-tech production is needed in Turkey. Even those who set out with the goal of domestic production leave domestic production aside and turn to imports. I wish I had the economic power and knowledge that I have now at a younger age, so that I could make bigger investments in the future when I first started. But at the moment, I still use both my knowledge and our economic resources as a source of investment for the future.

Enelsan is the first and only manufacturer of magnetic flowmeters in Turkey. This year, 1 billion dollars will be invested in water and wastewater projects. Even if there is a 5% measurement investment in this, we can say that there is a need for 50 million lira flowmeters. Today, almost all of this need is brought from abroad. Last year, we received an order for 40 flowmeters for Eti Maden's Kırka plant, which is a more difficult industry than water. This year, we received 80 more orders. We are currently manufacturing these flowmeters. Magnetic flowmeters need calibration. Over the years, we have gained a lot of knowledge about calibration with different methods. We received an Accreditation Certificate from Türkak 2 years ago. It is not possible to manufacture a flowmeter without accreditation and calibration. We first set up our infrastructure. We mainly focused on the production of electromagnetic flowmeters, but we also manufacture pressure transmitters. As we realize the gap in these technologies in the industry, we are evaluating these gaps. We also receive support from many organizations in this regard.

Mr. Ertan, what are the difficulties of working in the Turkish industry?

The job you received is canceled for various reasons or you may be excluded from the tender for another reason. We do not see such cancellations in Turkish projects of foreign brands, but rather in the tenders of our own municipalities.

When you started your work in the sector, was there a need for domestic production?

Before 1980, Süleyman Demirel; We lived such a period when he said, 'We needed 70 cents'. If I had not intervened in a biscuit factory struggling with many problems at that time, biscuits would not have been produced in that facility. During this period, we have always overcome problems with domestic solutions. Since we did not have any capital, we experienced periods when we tried to do what anyone told us to do. We have also built 200 ovens in the sector. A facility wanted to manage the furnaces previously manufactured with automation. If there is no homogeneous heat distribution in an oven, it is almost impossible to install an automation system in this oven. For this, we started to manufacture ovens with homogeneous heat distribution, where automation can be used. The concept and approach are always the same. We approached problems with more rational solutions. While we find temporary solutions to the problems and only serve to continue the production, we are doing improvement works today.

Do you also do the production in-house?

We currently have our products made of stainless-steel casting. While sanding these products, they are sanded with steel balls and there is a rusty surface on them. We had to set up an electropolishing plant for him. There is no need for a large bench investment for these equipments after knowledge is acquired. Currently, we can order 5 thousand electrodes at a time. Electrodes on the CNC machine can be produced much cheaper than us and much faster. Instead of pulling a thread into the shaft, we order the bolter for it. After manufacturing many parts in this way, we can assemble them here. What is important to us is the knowledge and calibration feature of this device. Our products reach the customer with their calibration certificates.

Which sectors do you expect to receive the most demand in the coming period in Turkey?

We aim to export higher volumes in the coming period. I actually predict that there will be a particularly serious demand in the water industry. Turkey needs to invest 60 billion dollars in order to bring its infrastructure to European standards. During a visit I made to the Southeast recently, I saw that water does not flow from the fountains in many villages yet. Many cities do not even have a wastewater facility concept. If these investments are not made, we do not have a chance to enter the European Union. In the fact, we recently measured a drinking water treatment plant in Bulancak, Giresun. Support is received from Europe for the project part, but when it comes to investment, credit is given and materials are purchased from Europe. This is how the procedure works. This is why all the big brands in Turkey are in a rush right now. Foreign brands offer their proposals below their costs in Turkey so that they can get the job. A domestic manufacturer has no chance to compete here. Currently, overseas brands are trying to bid cheaper than us in many tenders. Another business owner, who received a price from us, said that he placed an order for the product in China and that he would bring the product from there. The product we are talking about is a flowmeter weighing 250 kilograms. If you bring it by ship, you cannot bring it to Turkey in 6 months. Maybe there is a cheaper production than us in China, but we are talking about 7 thousand kilometers. The product you ordered is coming here by plane. The difference between the product he bought from China and us is already around 500 dollars.For the product you bought from Turkey, you will find instant contact and service in a shorter time.

So, what kind of advantages do you provide in terms of calibration?

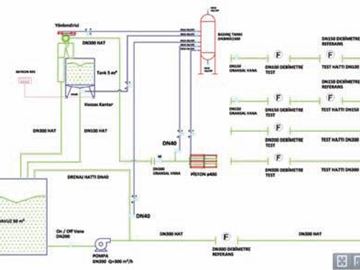

Here we do calibrate. When we calibrate flowmeters, for which some big brands specify an accuracy of 2 per thousand in their calibration certificates, we detect an error of 3 or 5 percent. This is not an easily detectable error. If we are talking about the flow, you should have a real reference. A few years ago, we gave Ankara ASKİ such a flowmeter. They tried to measure the accuracy of the flowmeter by filling a large pool. When I asked how many millimeters of accuracy they measure the pool measurement here, he replied 2 millimeters. The pool was 30 meters by 20 meters in size. The difference of 1 millimeter here corresponds to 6 cubic meters. If the device is measured, we are talking about a device that passes 6 cubic meters per hour. It is not possible to read the flow rate with the level. Maybe it can be done in very large volumes, but for the capacity we mentioned, this measurement is meaningless. We have a calibration station accredited by Türkak, which can be traced on the basis of weight. After this process, we print Türkak's seal. We have a dry summer ahead of us. We need to realize the water distribution in the most efficient way. We can only know by measurement whether we have made this distribution correctly. In a system we established for Izmit Municipality, we offered a solution that both measures and balances the flow. Here, you need to be able to measure the flow in order to know which valve will open how much and how much water is sent to where.

On which sectors does Enelsan mainly concentrate?

We serve mostly for the water industry with our magnetic flowmeters. There are 195 factories in Dilovası organized industrial zone. All of these 195 factories have a magnetic flowmeter at the exit and a central purification system is used here. The central treatment system was built with a build-operate-transfer model. The organized industrial zone pays the operator of this facility every month for its discharge. In order to collect this price in the most fair way, you need to measure again. We gave a flowmeter to every company here. These flowmeters are read at the beginning of the month and the waste is billed to the enterprise according to the discharge amount read here. They wanted measurement at an open weir for a treatment plant. We can do that too. Weir measurement; When flowing water in a certain section in an open area, the height of this water is an expression of the flow rate. Here, the relationship between level and flow is not linear. We take this even further. We calibrate these weirs with a healthy magnetic flowmeter. While calibrating, we write to the memory of our measuring device which flow rate each millimeter corresponds to. Then we get a device that reads accurately. An accuracy of 3 percent is accepted for open weir measurement. We manufacture open weir solutions with accuracy below one percent.

The chemical industry has not yet developed much in Turkey. If there is a growth here, then we have the potential to offer solutions in the chemical industry, but we also have shortcomings here. Big chemical companies are planning their products by manufacturing abroad, concentrating here and diluting them. So we're talking about a small market here. If there are new investments in this regard, then we will also be in the chemical industry. We can also offer hygienic flowmeters to filling machine manufacturers.We offer completely stainless steel products with connections and body. A minimum of two years is required for a product to be recognized. Although we have a very large marketing activity, we even started to have difficulties in meeting the incoming demands.

What are your plans for the next period in the process automation sector?

Let's take a sector assessment from you for the past year and 2014. There is very little investment in the sector. Today, not much investment is made for the process automation sector. Even in very simple processes, you have the chance to collect the data on a PLC and control the production from the center with an automation system. After receiving the data, you have the chance to decide and direct the application or production. The important thing here is the correct reading of the field devices.

Do you read the level and temperature correctly and did you use a product suitable for this process?

The answers to these questions are important. Previously, there was only one manometer on a reactor and we managed the process with this instrument. Now, as automation systems increase and PLC and software become more complex, there is a need for this information to come to a center, namely transmitters. There is also a temperature transmitter produced by Enelsan. We have now applied for CE certification. Our pressure transmitters are like our only magnetic flowmeters in Turkey. Process variables are pressure, level, temperature and flow. We can manufacture almost any field device. Today, we also have the knowledge to produce a mass flowmeter if it uses a mass flowmeter. Maybe 30-40 years ago, the Coriolis principle was used only by certain companies. Today, almost all manufacturers can produce this technology. We have our own design office, which consists of experts in the field. We use CADCAM software and plotter systems in this office. At the moment, we haven't started the manufacture of other instruments, as we haven't seen the potential in the magnetic flowmeter yet. Companies in Turkey should undertake the production of the most needed products. As the representative of a company that does not have a representative in Turkey, it is not possible for us to get anywhere with the logic of responding to the demands of these products. As a state policy, such innovative manufacturing is supported, but many companies still cannot go beyond representation. There is a Machinery Manufacturers Association in Turkey. The machine manufacturer makes laser cutting in Turkey. It brings laser cutting device and coordinate reader from abroad. Here, a sled is being made, and he bends and puts hair on the machine and says he manufactured a machine.