AUTOMATION MAGAZINE – JUNE INTERVIEW

Indispensable in Water Automation: Measurement Technology

One of the most important needs of environmental consultancy companies that offer solutions for water and wastewater, together with industrial institutions, is to know what is produced/consumed and how much. For example, the amount of raw material processed in an oil refinery is as important as the processing of that raw material. The need to measure the amount, density, temperature, pressure and similar properties of the fluid comes to the forefront not only in the field of petrochemistry, but also in many sectors with large-scale manufacturers such as agriculture, pharmaceutical-cosmetics, paper, machinery, metallurgy, and in water / sewage areas.

Various measurement instruments such as pressure/temperature transmitter, differential-pressure transmitter, brix meter and flowmeter are used for these measurement areas. Enelsan, the first company that brought the subject of measurement instruments to Turkey, has been active in the field of instruments and measurement technologies for many years. Enelsan, which works as a distributor with world-renowned companies in some of the products for which it offers marketing and maintenance services, continues to offer its own devices to the market in the field of electromagnetic flow meters.

One of the first instruments that comes to mind when it comes to industrial measurement is the density/brix meter. As it is known, one of the most important characteristics of liquid products or waste elements produced in factories is their density. The density factor is also an important standard for quality. Brix, a concept related to density measurement, expresses the amount of sucrose in grams in one hundred grams of liquid sugar solution. Chemical industry, petrochemical industry, beverage and sugar industry, food industry, mineral oil industry, cement industry, steel industry, paper and cellulose industry, machine construction and paint industry, electronics production and semi-conductors industry related to the usage areas of the density meters in question, Examples of environmental regulation systems and treatment plants can be given.

Density meters supplied by Enelsan, hydrocarbon, water-based solutions, liquid sugar, liquefied natural gas, liquid mixtures, fruit juice, chocolate, dough, oil, acid, alkaline solutions, alcohol, ammonia, paint, solvents, glue, foam in the above-mentioned areas and mud, cold and heat transfer media and similar elements. It has an accuracy of ± 0.2 kg/m³. According to its design, it can operate between -40°C and +210°C. The product consists of preamplifier, electronic transmitter, filter, gas separator and peripherals. Another prominent instrument group in measurement technology is pressure-temperature transmitters. As the name suggests, these transmitters are used to measure the pressure, absolute pressure and temperature of liquids, gases and steam.

There are many industries such as chemical, pharmaceutical, food industries and water distribution networks among its usage areas. One of the technologies used in pressure measurement is pressure measurement with the differential-pressure method. This method can be explained as the completion of the measurement by converting the difference between two different pressures recorded with the technical possibility provided by the product design to an analog output signal. Temperature transmitters, on the other hand, are devices based on temperature measurement and work with the principle of converting electrical information, which is a function of the temperature received from the probe, into meaningful automation standard signals. Generally, resistance variable such as PT100 or voltage variable products such as thermocouple are used as sensors. The transmitter linearizes the non-linear electrical information coming from here with compensations and displays it proportionally within the scale previously entered in the temperature transmitter device.

Enelsan temperature transmitters have a temperature measurement range between – 50 °C and +600 °C, and offer inset change without stopping the process. It includes the option of 2/3/4/6 wire connection terminals. There are stainless 316 casting head/plastic casting head options. The programmable analog output terminal has a value of 4-20 mA. Ex-proof feature, digital display and HART feature are other highlights of the product.

Flowmeter Solution in Water and Wastewater Processes

We call the water form, which is formed by human beings using and releasing water in line with their needs, wastewater. The type of wastewater differs as domestic wastewater and industrial wastewater according to the usage area of the water. Regardless of the nature of the wastewater generated due to its harmful content, it must be treated. Because these wastewater types refer to water that is polluted by the amount of organic and inorganic substances that the water does not naturally contain. This pollution, on the other hand, is a type of pollution that can cause serious environmental problems, especially in the industrial sense, which is in danger of getting into drinking water sources.

Health standards are as important as economic requirements for the development of our country and for our people to achieve more prosperous conditions. The most tangible area that touches the health issue is the food area. Food companies and drinking water producers are among the most influential actors in determining our eating and drinking habits and the quality in this area. One of the indispensable elements for the production quality of companies in this sector is measurement technology. As a matter of fact, the most common usage areas of magnetic flow meters are water, wastewater and treatment systems. Information about which product is produced in how much, at what density, in which temperature and pressure range is provided by means of measuring instruments.

Another factor that comes to mind when it comes to health and environment is the environment in which one lives. As it is known, our country is a production base with world-class production facilities. It is a fact that this location has environmental disadvantages as well as economic advantages. It has become necessary to measure and control the amount of waste water and waste material in order to reduce and, if possible, eliminate these disadvantages. The role of measuring instruments is also evident in the measurement and control of water, wastewater and waste material. The more quality measurements are made, the more quality standards can be achieved in terms of the environment.

There are various instruments used for flow measurement in large-scale facilities such as industrial treatment plants and drinking water filling plants. Open channel flow meters, flow switches, vortex meters, ultrasonic flow meters, mass flow meters, oval wheel counters designed for different usage conditions and different needs are some of them. One of the devices that provides the most comprehensive service on the subject is electromagnetic flowmeter.

Electromagnetic flowmeters work according to Faraday's Law of Induction. A fluid with electrical conductivity passes through a magnetic field in an electrically insulated pipe. A pair of coils is used to create a magnetic field, and an electric current is passed through these coils. A voltage is generated between the electrodes that is directly proportional to the flow rate of the liquid. This voltage changes depending on the flow rate (Q), flow rate (v), geometric correction coefficient (k), also known as the body coefficient, magnetic field size (B) and flowmeter inner diameter (D).

Q=f(v,k,B,D) and Q=v*(k*D*B)

Magnetic field, inner diameter and body coefficient are fixed values. Therefore, equality; It can be expressed as Q= v*(k*D*B)=v*K and it is seen that there is a linear relationship between the flow rate and the generated voltage.

The voltage signals detected by the electrodes are made intelligible with a signal converter.

Electromagnetic flowmeters offer much more precise measurement capability than many flowmeter types. Since electromagnetism data is used for measurement, the probability of mechanical failure is lower and there is no possibility of clogging, explosion, etc. The hazards are also lower compared to other flow meters. In the manufacture of electromagnetic flowmeters, ebonite, ceramic and Teflon coating types are used for the areas where they will be used. Again, different materials are used for different areas of use for the ability of the products to withstand temperature.

Electromagnetic flowmeters introduced to the market within the body of Enelsan, Turkey's first and only domestic electromagnetic flowmeter manufacturer, have to be produced by going through highly sensitive processes in terms of technology. These flow meters, which are responsible for measuring the flow rate of many kinds of liquids in any production facility, come to the fore with their margin of error compared to alternative brand productions. The technological know-how that comes from having partnerships with worldwide companies for many years has been combined with the optimization of domestic needs in Enelsan laboratories. When the ease of transportation and synchronization advantage brought by being domestic are added to this synthesis, it is predicted that it will be much more advantageous to work with local service providers in measurement technology.

Electromagnetic flowmeter model ETRANS-M 210 produced by Enelsan for water and wastewater processes. Separate or compact model options have been determined for the approved ebonite inner body coated flowmeter for drinking water. The device, whose electrode type is stainless steel and which measures fluids up to 80⁰C, can be produced in various sizes for various needs.

The Inseparable Duo in Measurement Technology: Statistics and Calibration

In industrial terms, measurement quality is of course important, but another factor as important as quality is ensuring the continuity of quality. The most valid solution used to ensure this continuity is the calibration service. Calibration service, which we can define as the elimination of the decrease in measurement sensitivity in the products used over time, is perhaps the most important of the production and after-sales service stages. Enelsan, which also offers very suitable solutions at this point, meets the electromagnetic flowmeter calibration demands that it receives regardless of the brand.

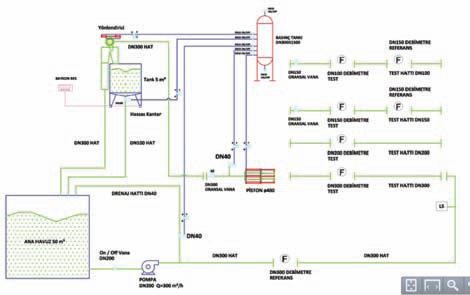

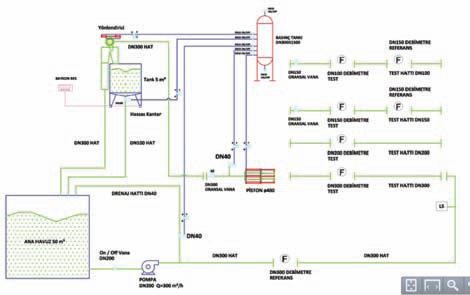

Turkey's first and only TÜRKAK accredited flowmeter calibration laboratory owned by the private sector is located within Enelsan. Apart from the laboratory, there is a pool with a water capacity of 50 tons. From here, it is possible to calibrate with uncertainty values ranging from 0.18% to 0.55% up to the upper limits of 700 m3/h by means of a frequency-controlled pump at various flow rates and pressures and 3 reference flow meters in different diameters. Weighing system and reference flow meter system, the methods used in the calibration process.

Last word

Enelsan, which offers efficient solutions for measurement services in the food and waste counting sectors, has adopted the motto of taking domestic production technology to the next level and serving our own country with our own products, based on the slogan “Turkey: Discover the Potential” determined by our country in 2014. While a waiting period for each service is considered reasonable, since the waiting period for services in the health field can be life-threatening, choosing a domestic service in the field of water and wastewater – and related environment – can often be a much faster and more practical solution. Being aware of this situation, Enelsan is working towards fulfilling the requirements of its responsibility; It considers it their duty to make progress at the point of providing added value to our country.

Working with the satisfaction of being a member of the domestic production process and having an important quality standardization, Enelsan considers that quality control processes are not only related to the inspection of institutions but also to the inspection of the public, therefore, internet platforms should also be actively used in order to follow up its products and services and convey opinions and suggestions. in his opinion. For this reason, while continuous updating studies are provided, the company's web address Efforts are made to use www.enelsan.com with maximum efficiency.