Water and Wastewater Processes: Importance, Functioning and Monitoring with Measurement Instruments

Water and Wastewater Processes: Importance, Functioning and Monitoring with Measurement Instruments

Water and wastewater processes are a critical industrial area that involves the treatment, processing and management of water. These processes are used for various purposes, such as providing drinking water, recycling water used in industrial production, treating wastewater and protecting the environment.

The proper functioning of water and wastewater processes contributes to human health, environmental protection and the sustainability of industrial activities.

Importance of Water and Wastewater Processes The importance of water and wastewater processes are as follows:

1. Drinking Water Treatment: Water and wastewater processes are an essential component of drinking water treatment. The processes of water intake, treatment, filtration and disinfection ensure that drinking water is safe and healthy.

2. Industrial Use: Water is a vital resource used in many industrial processes. Water and wastewater processes play an important role in recycling and treating water used in industrial plants.

3. Wastewater Treatment: The treatment of industrial and domestic wastewater is critical for the prevention of environmental pollution. Water and wastewater processes remove harmful pollutants from wastewater.

4. Flood Control: Water and wastewater processes are used for stormwater management and flood control. Water management infrastructure prevents the uncontrolled flow of water and reduces flood risk.

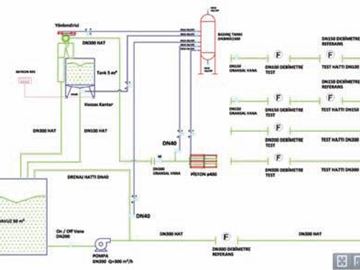

For the Water and Wastewater Process, I would like to talk about our project called "Innovative Wastewater Monitoring System" related to the wastewater treatment plant we recently built in Çorlu Leather OIZ.

Enelsan Endüstriyel Elektronik San. AŞ: Innovative Wastewater Monitoring System in Çorlu Leather OIZ

Environmental awareness and sustainability are becoming increasingly important in today's industry. Wastewater management and monitoring plays a critical role in minimizing environmental impacts and efficient use of resources, especially in industrial zones. At this point, the open channel flowmeter application developed by Enelsan Endüstriyel Elektronik AŞ makes a significant contribution to environmental sustainability in Çorlu Leather Organized Industrial Zone (OIZ).

Innovative Technology and Original Products

Enelsan Endüstriyel Elektronik AŞ is known as a pioneer in industrial electronics solutions. With years of experience and engineering expertise, our company offers unique solutions to various sectors. The Çorlu Leather OIZ project is one of these solutions.

Open Channel Flowmeter Application: An Innovative Step for Environmental Efficiency

The wastewater monitoring system at Çorlu Leather OIZ is powered by an open channel flow meter application developed by Enelsan Endüstriyel Elektronik AŞ. This application offers the possibility to

monitor wastewater flows online with a monitoring system of 90 units. The innovative structure of the system is designed to minimize environmental impacts and optimize wastewater management.

Features that Make a Difference

Online Monitoring and Analysis: The open channel flow meter application monitors and analyzes wastewater flows online. This enables instant data collection and accurate decision making.

High Precision and Reliability: Enelsan Endüstriyel Elektronik AŞ's technology offers high precision and reliability. This enables accurate measurement of wastewater flows and increases process efficiency.

Easy Integration and Operation: The open channel flow meter app offers easy integration and use. This allows businesses to seamlessly integrate with their systems and provides a user-friendly experience.

The open channel flow meter application developed by Enelsan Endüstriyel Elektronik AŞ makes an important contribution to the wastewater management in Çorlu Leather OIZ. With its innovative technology and unique products, Enelsan Endüstriyel Elektronik AŞ is a leader in supporting environmental sustainability and providing solutions tailored to the needs of industrial enterprises.

We can classify the products used in these and similar areas under the following main headings.

Use of Open Channel Flowmeters

Water and wastewater processes are critical to the efficient treatment, processing and management of water. The proper functioning of these processes ensures the safe and healthy use of water, helps reduce environmental damage and ensures the sustainability of industrial operations. Metering devices such as open channel flow meters help to effectively monitor and manage water and wastewater processes, thereby ensuring environmental compliance and improving operational efficiency. Therefore, effective management and measurement of water and wastewater processes is essential for the sustainability of water resources and environmental protection.

What is an Open Channel Flowmeter?

Open channel flow meters are devices used to measure the rate at which water or other liquids pass through an open channel. Such flowmeters are often used in open environments such as rivers, canals, stream beds, treatment plants and irrigation canals.

Open channel flow meters are used in a variety of important applications in water and wastewater processes:

1. Monitoring Changes in Flow: Open channel flow meters help to evaluate the efficiency of the process by monitoring changes in water flow rate.

2. Flood Control: Open channel flow meters are used to monitor and manage flood risk in stormwater drainage systems and flood control applications.

3. Wastewater Treatment Plant Performance Monitoring: In wastewater treatment plants, open channel flow meters are used to monitor and optimize the performance of the treatment plant.

4. Efficiency and Cost Optimization: Open channel flow meters are used to optimize operating costs by continuously monitoring the flow rate of water.

Use of Electromagnetic Flowmeters in Water and Wastewater Processes

Electromagnetic flowmeters are important measuring instruments used in water and wastewater processes. Reliable and accurate flow measurements are essential for effective management and monitoring of water and wastewater processes. Electromagnetic flowmeters offer an ideal solution to meet this need and help improve performance in water and wastewater processes.

What is an Electromagnetic Flowmeter?

Electromagnetic flowmeters use a technology based on electromagnetic principles to measure the flow rate of water. These devices directly measure the speed and volume of water within a pipeline. Electromagnetic flowmeters determine the flow rate by sensing changes in the conductivity of the water. Therefore, electromagnetic flowmeters are widely used in various applications such as drinking water, industrial water and wastewater.

Use in Water and Wastewater Processes The use of electromagnetic flowmeters in water and wastewater processes can be as follows:

1. In Wastewater Treatment Plants: Electromagnetic flowmeters are used in wastewater treatment plants for continuous measurement of wastewater flow rate. This helps to monitor and optimize the performance of the plant.

2. In Water Distribution Systems: Electromagnetic flow meters are used for measuring the flow rate of drinking water used in water distribution systems. This helps to reduce water loss and monitor water consumption.

3. In Industrial Processes: Electromagnetic flow meters are used to monitor and control the flow rate of water used in industrial plants. This helps to optimize production processes and use water efficiently.

Use of Hydrostatic Level Sensors in Water and Wastewater Processes

Hydrostatic level sensors play an important role in water and wastewater processes. By precisely monitoring the level of water or wastewater, these sensors improve process efficiency, optimize storage capacity and reduce flood risk. Reliable and precise level measurement is essential for effective management and monitoring of water and wastewater processes, and hydrostatic level sensors fulfill this need.

What are Hydrostatic Level Sensors?

Hydrostatic level sensors are measuring instruments that use the principle of hydrostatic pressure to measure the level of a liquid or wastewater. These sensors determine the level by measuring the difference in hydrostatic pressure from the surface of the water or wastewater to the point of measurement. They usually include a pressure sensor and an underwater hose or probe.

Utilization in Water and Wastewater Processes

Hydrostatic level sensors can be used in water and wastewater processes in the following ways:

1. Storage Tanks: In water and wastewater processes it is important to monitor the level of storage tanks. Hydrostatic level sensors help to control storage capacity by continuously measuring the level of water or wastewater inside the tank.

2. Treatment Ponds: In wastewater treatment plants, it is important to monitor the level of the treatment basins. Hydrostatic level sensors help to improve the efficiency of the process by determining the level of fullness of the basins.

3. Pump Stations: Level control of pump stations is important in water and wastewater processes. Hydrostatic level sensors monitor the level of pump stations, optimizing pump runtime and saving energy.

4. Flood Control: Hydrostatic level sensors can be used to monitor and control flood risk in stormwater drainage systems. These sensors prevent flooding by monitoring the level of storage tanks where rainwater is collected.

Radar Level Sensors

What is a Radar Level Sensor?

Radar level sensors are devices used to measure the level of liquid or solid materials in a tank, silo, warehouse or other enclosed or open space. These sensors work based on radar principles and can measure levels with high precision and reliability.

Here are some highlights of the use of radar level sensors in water and wastewater processes:

Precision and Reliability: Radar level sensors are ideal for precisely measuring the level of liquids such as water and wastewater. Thanks to their high accuracy, they provide reliable measurements even under variable process conditions.

Use in Various Environments: Radar level sensors can be used in a wide range of media, suitable for measuring clean water, wastewater, chemical effluents and other liquids.

Withstanding Harsh Environments: The environments in water and wastewater processes are often harsh. Radar level sensors are designed to withstand such environments. They are resistant to chemical influences, high temperatures and pressure changes.

High Measurement Range: Radar level sensors can often be used over long measuring ranges. This is ideal in applications such as deep tanks or high volume water tanks.

Ineffectiveness of Waves and Foam: Factors such as waves and foam, which are common in water and wastewater processes, do not affect radar level sensors. These sensors easily detect movements and changes on the surface.

Automation and Remote Monitoring: Radar level sensors can be integrated with automation systems and used in combination with remote monitoring systems. This enables automated control of water and wastewater processes and provides operators with real-time data.

Radar level sensors offer an easy-to-use, reliable and flexible measurement solution for water and wastewater processes. They are considered a valuable tool for increasing process efficiency and reducing operational costs.

Pressure Transmitters

What is a Pressure Transmitter?

Pressure transmitters consist of pressure sensors and electronic circuitry. Pressure sensors are a type of sensor that detect pressure changes and converts these changes into electrical signals. These sensors

can operate in different pressure ranges and measure different types of pressure (hydrostatic, differential, absolute, etc.).

Here are some highlights of the use of pressure transmitters in water and wastewater processes:

Level Measurement: Pressure transmitters can be used to measure the level of water and wastewater tanks. The water or wastewater level can be determined through pressure changes inside the tank. This information helps to determine and manage the amount of water or wastewater in the tank.

Pressure Control: In water and wastewater processes, it is important to monitor and control pressure changes that may occur in pipelines or tanks. Pressure transmitters detect pressure changes in the system and transmit this information to control systems to provide the desired pressure levels.

Control of Pumps: Monitoring and controlling the performance of pumps in water and wastewater processes can increase efficiency and reduce energy consumption. Pressure transmitters measure the pump operating pressure and ensure that the pump is operating efficiently.

Leak Detection: Pressure transmitters can be used to detect leaks in water or wastewater pipelines. Pressure drops or sudden changes in the pipeline can indicate a possible leak and alert system operators.

Automation Integration: Pressure transmitters can be integrated with automation systems of water and wastewater processes. This enables automatic control and monitoring of processes, provides operators with real-time data and increases process efficiency.

Durability and Reliability: It is important that equipment used in water and wastewater processes is durable and reliable. Pressure transmitters are often designed to withstand harsh conditions and have a long service life.

In conclusion, pressure transmitters are an important measuring instrument widely used in water and wastewater processes. They offer an ideal solution for many applications in water and wastewater plants and are considered a valuable tool for improving process efficiency.

We have prepared this article to highlight our important role in water and wastewater processes and the solutions we offer. From open channel flowmeters to electromagnetic flowmeters, hydrostatic level transmitters to radar level sensors and pressure transmitters, we offer solutions to the needs of the water and wastewater industry. We are here to meet our customers' requirements for effective management of water and efficiency of processes. Please contact us for more information about our products or to get in touch with us for solutions tailored to your needs. We will be happy to help you.

If you want us to be a partner in your solutions, you can contact us at satis@enelsan.com or +90 262 754 6313.