ULTRASONIC FLOW AND CALORIE MEASUREMENT SYSTEM

In order to provide high precision and accuracy in calorie measurement, the flow measurement method operating on the ultrasonic principle and temperature measurement with the PT100 temperature sensor are used.

The main unit calculates calories by estimating the energy difference between the temperature sensors according to the flow rate it receives and the temperature difference between the 2 temperature sensors. Ultrasonic calorie measurement system manages to calculate calories in the following units.

➢ Giga Joule ( GJ )

➢ Kilocalories ( KC )

➢ Kwh

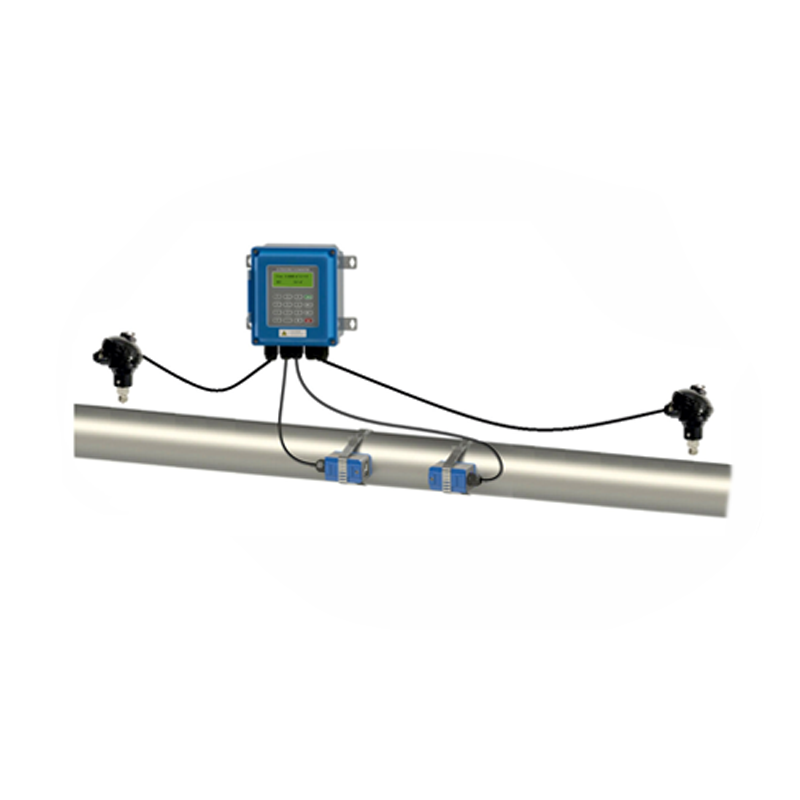

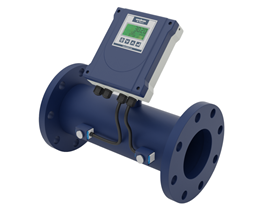

➢ BTU The basic parts of the system consist of flow measurement sensors that allow measurement from outside the pipe,

produce high-frequency sound and detect the return of this signal, temperature sensors that detect the inlet and outlet temperatures with high sensitivity and transmit them to the main unit, and the main unit that performs all calculations and operations according to the information it receives.

The main unit measures the inlet and outlet temperature. It calculates calories by calculating the energy difference between these 2 points with the flow measurement made using this temperature difference. The system transfers this information to Modbus-Profibus converter via RS485Modbus output and calorie information is transferred as Profibus.

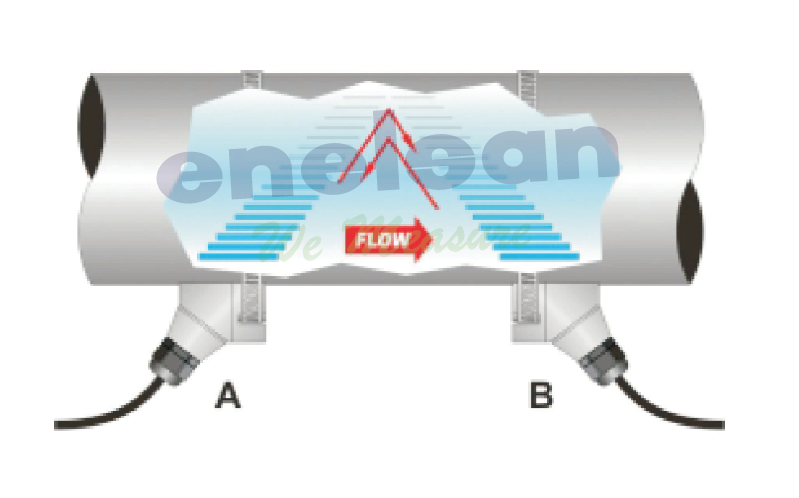

WORKING PRINCIPLE OF FLOWMETER / CALOMETER

Flowmeter / Calorimeter works by transmitting the high frequency sound at a certain angle in the pipe and detecting the reflected signal with the receiver sensor. When there is no flow, there is a difference between the time it takes for this signal to be generated and returned, and the time spent with the translation of the signals depending on the flow rate in the pipe. The system calculates the velocity of the fluid by calculating this difference.For this reason, this working principle is called transit time.

In this system, there is 1 signal generator sensor and 1 signal detecting sensor operating in connection with the main unit. According to the pipe information entered in the main unit, the installation distance is determined by the main unit and notified to the user, and the sensor is mounted according to this information.

The information entered in the main unit is pipe type, fluid type, pipe diameter and wall thickness. According to this information, the required distance between 2 sensors is calculated by the main unit.

After installation, the correct signal strength can be monitored by the main unit, and the main unit helps to fine-tune the signal quality to be the most accurate. The system gauges the flow rate with the help of these sensors and calculates the calories by using the temperature difference between the temperature sensors.

Temperature sensors are placed at 2 points where the energy difference is desired to be calculated. In general, in cooling or heating systems, one of the temperature sensors is placed at the beginning of the input unit and the other sensor is placed at the end of the collection or output unit, and is used to calculate the entire energy consumed in the system.

Apart from this, the energy consumption of a single machine, the energy consumption of the heating system, etc., by placing temperature sensors only at the entrance and exit of the points to be calculated, this system is also used for the purpose of calculating the calories of these regions only.